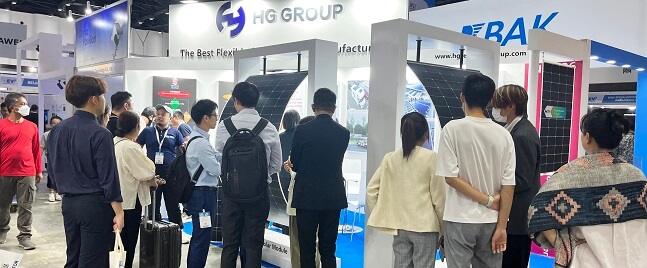

////// Flexible PV Module Mfr

-

Our Businesses

Residential Projects

HG solar modules combine the best features of cell technologies to achieve best performance levels at your service, which ensures HG solar modules achieve maximum luminous efficiency under real, day to day conditions, even under cloudy skies.

Know MoreCommercial Projects

With proven track record of reliability, durability, and cost-effectiveness, HG solar modules provide with over 25 years effective working time; HG solar modules have paved the way for a sustainable and cleaner future for commercial usage.

Know MoreUtility Projects

HG solar module, stand through extreme weather conditions and acid-base climate, due to its incredible durability and intelligent design; HG solar modules are packed with features that have rapidly made them a favorite for solar modules around the globe utility projects.

Know More -

Locations

Welcome to HG Group

You are currently on the HG Group Global Website.

You can come and have a factory inspection visit, we are so gladly to introduce to you our most advanced production line in the world..

Supported by Google Maps

-

Contact Us

Contact Us

Do you have any queries about the products or company?

Please do not hesitate to submit your concern.

Factory Location: Chongqing, China

Your Inquiry (Boxes marked * are mandatory.)

A New Era in Solar Power is Here

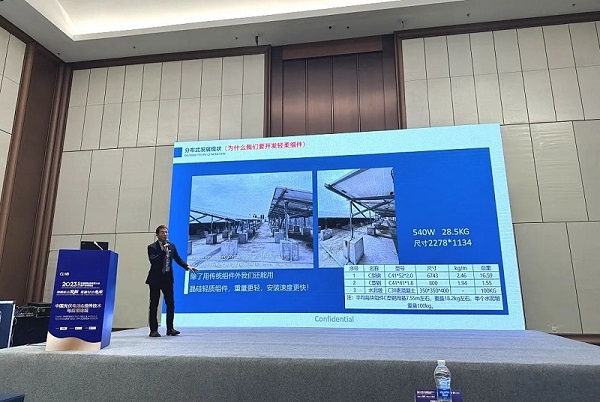

HG Group Participated PV Cell, Module Tech Devt and App Economics Forum

Recently, the 8th International New Energy Conference & China Solar Cell and Module Technology Development and Application Economy Forum was grandly held in Changsha International Convention and Exhibition Center. As one of the highly professional events in the photovoltaic industry, Huaneng, Sun Yat-sen University, JA Solar, DAsolar, Risen, HG GROUP, Jietai, Huasheng, and Yubang were specially invited for this closed-door module spot index meeting , Lucky and many other important guests gave speeches.

Among them, Pan Meng, President of HG Group, was invited to attend the meeting, and delivered a speech on the theme of "Application of Flexible Modules in Distributed and Integrated Photovoltaic Buildings", introducing the related technologies of Flexible Modules and the superior performance of outdoor empirical results. And shared the development status of distributed photovoltaics and the actual installation cases of BIPV.

At the forum site, Pan Meng explained various performances such as the structure and temperature characteristics of the flexible module backsheet; white, black, transparent grid and other color backsheets can be selected according to architectural needs. By continuously optimizing the thickness, weight, temperature and other parameters of the module structure, the reliability during the building installation process is enhanced.

At the same time, it shows the outdoor demonstration results obtained from multiple research and tests of HG flexible modules. The data shows that the flexible modules made of composite materials such as ETFE and PET have excellent performance in terms of moisture and heat aging resistance and light flexibility: a wide range of operating temperatures from -40 to 80°C, the light decay is less than 2% in the first year, and no longer after 25 years of use. Lower than 84.8% of the nominal power, using better packaging materials to improve the anti-PID performance of the module can make the working environment of the module more extensive. The flexible modules made of composite materials only weigh 3kg/㎡, which is 70% lower than conventional glass modules, and are suitable for buildings that cannot be safely supported due to insufficient load.

HG flexible modules can be used in various application scenarios such as floating on the sea; roofs, floors, curtain walls, special-shaped structures of buildings on land, and airships.

As the leader of high-quality products in the photovoltaic industry, HG GROUP firmly chooses flexible modules in the module route, and continues to innovate beyond itself, so that high-quality products can serve more users in the full cycle.

Last Updated: May 10th, 2023